In the world of sustainable engineering, energy efficiency is a crucial focal point. As we shift towards more sustainable practices in both industry and daily life, the role of mechanical components, particularly gears, becomes more significant than ever. Gears are fundamental elements in machines, from wind turbines to electric vehicles (EVs), influencing how energy is transferred, used, and conserved. The design and optimization of gears can directly impact the overall energy efficiency of these systems, which is essential for reducing energy consumption and minimizing the carbon footprint.

This article will explore the intricate relationship between gears and energy efficiency, examining how gear designs, materials, and configurations contribute to sustainable engineering solutions. By understanding how gears function and their role in energy transfer, engineers can make informed decisions that optimize performance, minimize waste, and increase the longevity of systems.

1. The Role of Gears in Energy Transfer

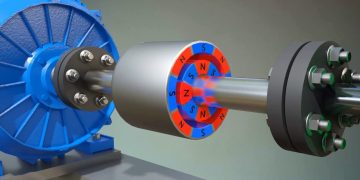

At the core of any mechanical system, gears play a vital role in transferring energy from one component to another. Their primary function is to convert rotational energy, adjusting speed, torque, and direction to meet the needs of the system. Whether in an industrial motor, a bicycle, or a wind turbine, gears allow energy to be transmitted efficiently across different mechanical parts.

Gears are designed to mesh smoothly, with minimal energy loss during transmission. However, this process isn’t entirely frictionless. Every time gears mesh, a small amount of energy is lost as heat due to friction between the teeth. In traditional gear systems, this friction can lead to significant inefficiencies, particularly in high-torque applications. Over time, this loss of energy can accumulate, affecting the overall efficiency of the system.

How Gear Efficiency Affects Energy Use

The efficiency of gears is quantified by their mechanical efficiency, which is the ratio of the useful power output to the total input power. In an ideal scenario, a gear system would have 100% efficiency, with no energy loss. In reality, losses occur due to factors such as friction, heat generation, and material deformations. The more efficient the gear system, the less energy is wasted, and the less energy is required to perform a specific task.

For sustainable engineering, this is critical. Minimizing energy loss translates to less energy consumption, which in turn reduces the environmental impact of the system. In renewable energy applications, such as wind turbines or solar trackers, efficient gears ensure that the energy captured from natural resources is effectively converted into usable power, rather than being lost through mechanical inefficiencies.

2. Gear Design: Optimizing for Efficiency

When it comes to sustainable engineering, the design of gears is crucial for maximizing energy efficiency. There are several factors that engineers consider when designing gears to ensure they minimize energy loss while still fulfilling their required mechanical functions.

Gear Tooth Profile

The tooth profile is one of the most critical aspects of gear design. Gears are typically classified based on their tooth geometry, including types like spur gears, helical gears, bevel gears, and worm gears. The shape and alignment of the teeth influence how smoothly they mesh, affecting both the efficiency and lifespan of the gear system.

- Spur gears, the most basic type, have straight teeth that are parallel to the axis of rotation. While they are easy to manufacture, they can generate a lot of noise and vibrations, which can lead to energy losses.

- Helical gears, on the other hand, feature angled teeth that engage more gradually, which reduces noise and friction. The gradual engagement of teeth leads to smoother operation and higher efficiency.

- Bevel gears are often used when power needs to be transmitted at an angle, and their efficiency depends on their precision and the quality of the tooth contact.

- Worm gears are known for their ability to provide high torque, but they are also more prone to energy losses due to their non-parallel teeth and the sliding motion between them.

For maximum energy efficiency, engineers often opt for gears that exhibit the least friction and wear, such as helical gears, especially when operating under high loads.

Material Selection

The material from which gears are made plays an essential role in their energy efficiency. Traditional gear materials include metals such as steel, cast iron, and bronze, which offer durability and strength. However, the downside of using metal gears is the significant friction and wear over time, leading to energy loss.

In sustainable engineering, there is increasing interest in the use of composite materials and coatings that reduce friction and wear. For example, carbon-based composites or ceramic materials are gaining traction for gears in high-efficiency applications, especially in electric vehicles and renewable energy systems. These materials can reduce the amount of energy lost to friction and help the gears last longer, further enhancing the sustainability of the system.

Moreover, lubrication is a key factor in reducing friction. The right lubricant can minimize wear on gear teeth and maintain the gear’s smooth operation over time, ensuring that energy losses due to friction are kept to a minimum. For example, in wind turbines, the use of biodegradable oils ensures that the systems operate efficiently while remaining environmentally friendly.

3. Gear Efficiency in Renewable Energy Systems

One of the most exciting applications of gears in sustainable engineering is in the realm of renewable energy. Whether it’s wind, solar, or hydro energy, gears are often used to transfer energy from natural resources to the electrical grid. To ensure that energy is used effectively, engineers must focus on optimizing gear systems for maximum efficiency.

Wind Turbines

Wind turbines convert the kinetic energy of wind into electrical energy. Gears play a pivotal role in this process by converting the low-speed rotation of the turbine blades into the high-speed rotation needed to generate electricity. However, in traditional wind turbine systems, gear inefficiencies can reduce the overall energy yield.

To maximize energy efficiency, modern wind turbines often employ planetary gear systems. These systems allow for a compact, multi-stage reduction of the turbine’s speed, which minimizes energy loss while increasing torque. Additionally, many wind turbines now use direct-drive systems, which eliminate the need for traditional gearing altogether, reducing mechanical losses and maintenance needs.

While these advancements improve energy efficiency, wind turbine designers also focus on reducing the weight and material usage of the gear components, further contributing to the sustainability of the system.

Solar Trackers

Solar trackers, which adjust the position of solar panels to follow the sun, also rely on gears for efficient operation. These devices often use slew drives, which are compact gear systems that provide high torque with minimal energy consumption. Slew drives allow solar panels to rotate smoothly while maintaining the stability needed to withstand wind and weather conditions.

In solar energy systems, optimizing the efficiency of the gears in trackers is essential for maximizing the amount of sunlight captured by the panels. By reducing the friction and wear on gears, the system operates more efficiently, ensuring that more energy is harvested from the sun.

4. Gears in Electric Vehicles (EVs)

Electric vehicles (EVs) represent one of the most significant advances in sustainable engineering. In EVs, energy efficiency is paramount, as the goal is to maximize the distance traveled per unit of electricity consumed. Gears in electric vehicle drivetrains help manage the conversion of energy from the electric motor to the wheels, ensuring that power is transferred efficiently.

Transmission in EVs

Unlike traditional internal combustion engine (ICE) vehicles, which use multi-gear transmissions, many EVs use a single-speed transmission. The electric motor in an EV operates efficiently across a wide range of speeds, eliminating the need for multiple gears to shift. However, some electric vehicles, particularly high-performance models, use multi-speed gearboxes to optimize power delivery at different speeds.

For these systems, the efficiency of the gearset is crucial for overall energy consumption. As with other renewable energy applications, the goal is to reduce friction and wear in the gears to ensure that the electric motor’s output is transmitted with minimal loss.

Regenerative Braking

One area where gears contribute to energy efficiency in EVs is regenerative braking. When the vehicle slows down, the electric motor reverses its role and generates electricity by converting kinetic energy back into electrical energy. This process helps recharge the vehicle’s battery, reducing the overall energy consumption. Gears in regenerative braking systems must be designed to handle the reverse energy flow efficiently to maximize the vehicle’s range and reduce reliance on external charging.

5. The Future of Gear Technology and Energy Efficiency

As sustainable engineering continues to evolve, so too does gear technology. Engineers are constantly working to innovate and create new materials, designs, and configurations that push the boundaries of energy efficiency.

3D-Printed Gears

One of the most exciting developments in gear technology is the use of 3D printing for creating custom gears. 3D printing allows engineers to design gears with complex geometries that were once impossible to produce using traditional methods. These gears can be optimized for reduced weight, lower friction, and better durability, all of which contribute to higher efficiency.

Additionally, 3D printing reduces material waste, making the manufacturing process more sustainable. As the technology becomes more refined, we can expect 3D-printed gears to play a larger role in the next generation of energy-efficient systems.

Smart Gears

The rise of smart materials and sensor technology also has the potential to revolutionize gear efficiency. Smart gears, embedded with sensors and monitoring systems, can adjust their operation in real time to reduce friction, optimize power transmission, and adapt to changing environmental conditions. This adaptive approach could further enhance energy efficiency in everything from industrial machinery to EVs.

Conclusion

Gears may seem like simple mechanical components, but they have a profound impact on energy efficiency in sustainable engineering. From wind turbines to electric vehicles, the optimization of gear systems can significantly reduce energy loss, minimize wear, and improve system longevity. By focusing on advanced designs, materials, and lubrication methods, engineers can continue to improve the energy efficiency of these crucial components. As gear technology continues to evolve, it will play an ever-greater role in making engineering systems more sustainable and energy-efficient, helping us transition towards a greener future.